Changwon Tunnel

High-Performance, Water-Based Ceiling Coating Improves Tunnel Visibility, Safety and Aesthetics

Changwon Tunnel maintenance team relies on new Kynar Aquatec® resin-based topcoat to achieve long-term durability, cleanliness and service life.

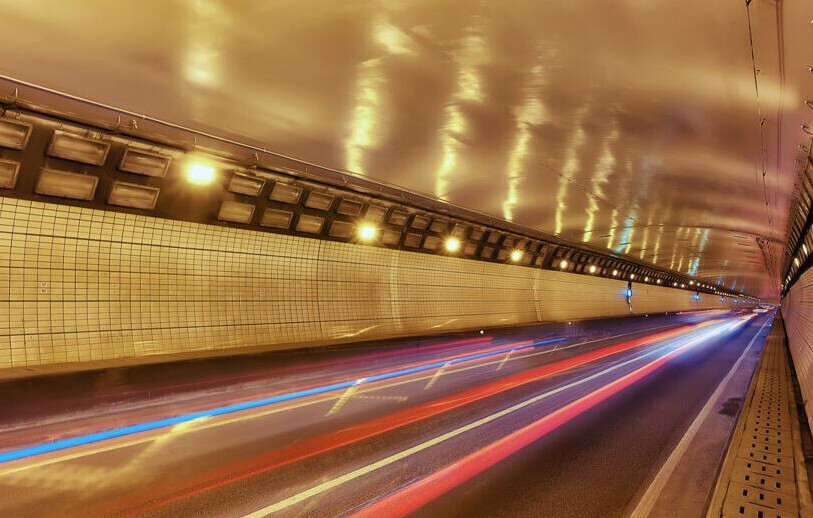

The four-lane Changwon Tunnel is located on road number 1020 in the South Gyeongsang Province of South Korea. The tunnel’s twin bores through the mountain are each approximately 7,677 feet (2340 m) long, 31 feet (9.4 m) wide and 15 feet (7.6 m) high (as measured from the roadway to the top of the tunnel arch). Southbound traffic experiences a significant descending gradient inside the tunnel, while northbound traffic experiences a corresponding ascending gradient. The two-lane descending tunnel was opened in 1993 and the two-lane ascending tunnel was opened in 1997.

Need to improve tunnel visibility and safety

The light-reflecting characteristics of a ceiling finish enhance the overall efficiency and effectiveness of tunnel interior lighting systems. The presence of moisture and engine exhaust products in the tunnel—especially emissions from diesel power trucks—creates an atmosphere that can darken unfinished surfaces, detracting from their light-reflecting qualities and the aesthetic impression it leaves upon users. The evaluation and selection process for tunnel finish materials must therefore consider reflectivity, adaptability, cleanability, durability and public safety considerations.

To improve illumination, visibility, cleanliness and safety within the Changwon Tunnel, the team responsible for maintaining the structure decided to paint the unfinished ceiling, which was dulling as a result of dirt and other airborne pollutants. Because the coating was to be applied inside the tunnel, the use of a low-VOC water-based coating was a key requirement. Other important coating performance characteristics desired were long-term durability, ability to resist dirt pick-up, biological growth accumulation, and other weathering factors, and retention of reflective value and color.

A clear choice

The process for selecting a high-performance coating for the tunnel’s ceiling started with a study over several months by AK Chemtech of nine different coating systems from various manufacturers, including Fluoroethylene vinyl ether (FEVE) resin-based coatings, polyurethane (PU) coatings and various waterborne acrylic coatings. The test results clearly showed that a new water-based PVDF coating, called AKUAFLON®, outperformed the other coatings in resisting dirt buildup.

Based on the study’s findings and other performance considerations, the maintenance team decided that the AKUAFLON® product from AK Chemtech would be the ceiling topcoat of choice for achieving the specific goals for the Changwon Tunnel project. AKUAFLON® coating is based on Kynar Aquatec® PVDF technology, an innovative platform of emulsions for producing ultra-durable water-based coatings that can be formulated with VOC levels below 100 grams/liter. Coatings containing these emulsions provide the long-lasting durability and excellent weatherability benefits of traditional Kynar 500® resin-based coatings and can easily be applied to a variety of substrates. Another benefit of the Kynar Aquatec® resin-based AKUAFLON® coating is its exceptional resistance to dirt pickup and biological growth that can reduce reflectivity.

Useful information

Kynar Aquatec® and Kynar 500® are registered trademarks of Arkema Inc.

AKUAFLON® is a registered trademark of AK Chemtech.

© Copyright 2021 Arkema Inc. All rights reserved.